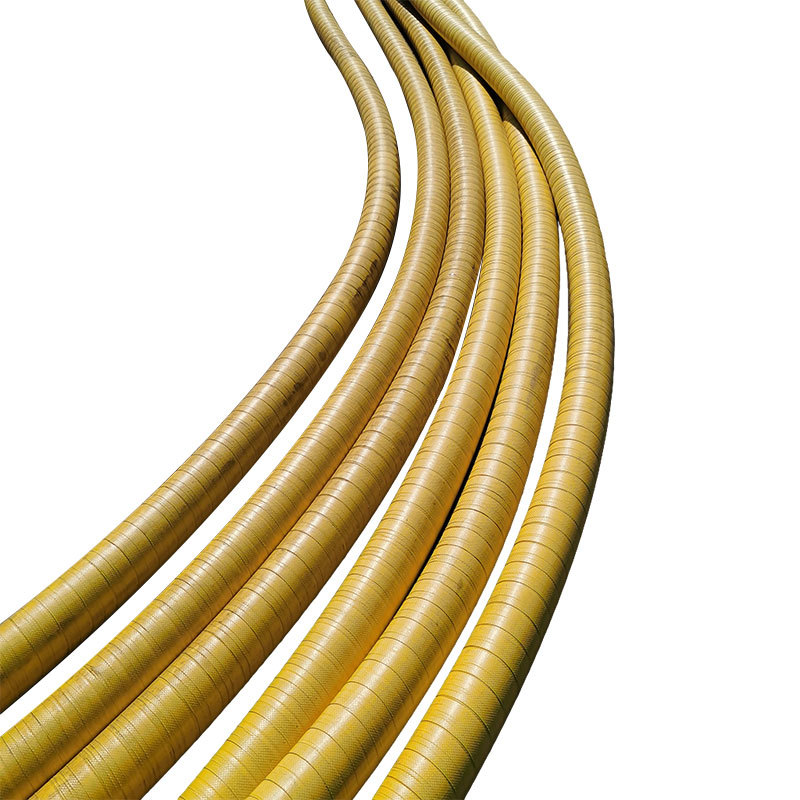

High-pressure rubber hose assembly for construction machinery

Keyword:

High-pressure rubber hose assembly for construction machinery

E-mail:

I. Our company produces high-pressure hose assemblies entirely from high-quality steel wire braided or spiraled rubber hoses and hose fittings, which are crimped together using specialized equipment. Depending on customer needs, we offer high-quality carbon steel, stainless steel, brass, and aluminum fittings. The forms and threads of the fittings strictly follow national metric standards (JB1891-1900-77), American standards, British standards, etc., ensuring accurate data, reasonable structure, convenient assembly, tight crimping, and no leakage or disconnection under high temperature, high pressure, and pulse operating conditions. This results in a high safety factor, long service life, and the ability to design and produce custom fittings and connectors according to user requirements.

II. The use of mediums and temperatures: oil -30°C to 80°C, air -30°C to 50°C, water 0°C to 80°C, for hydraulic power transmission or the conveyance of high-pressure mediums such as water, air, and oil to ensure the circulation of liquids and the transfer of liquid energy.

III. Hose joint and hose crimping methods:

1. External rubber stripping and crimping

Requires stripping a certain length of the outer rubber layer, suitable for GB/T 3683-92, GB/T 10544-03, DIN20022, SAE100R1A/R2A standards of steel wire braided hoses and steel wire wound hoses.

2. Non-external rubber stripping and crimping

The processing method is simple, suitable for fiber braided hoses and models like SAE100RIAT/R2AT steel wire braided hoses.

3. Internal and external rubber stripping and crimping

Requires stripping a certain length of both the inner and outer rubber layers, known as the internal lock type safety crimping hose joint, suitable for GB/T10544-89 large diameter tubes SAER12, DIN20023-4SH, and other ultra-high-pressure steel wire wound hoses.

IV. Hose joint and hose connection types:

1. Fully crimped high-pressure hose joints. 2. Detachable precision joints. 3. Vulcanized joints and low-pressure pipe fittings.

Connection forms with pipelines include: A. B. C. D. E. F. K. M. Q. WA. WB. WC. HD. HC and various other forms of hose assemblies.

Related products