Customized PTFE products

Keyword:

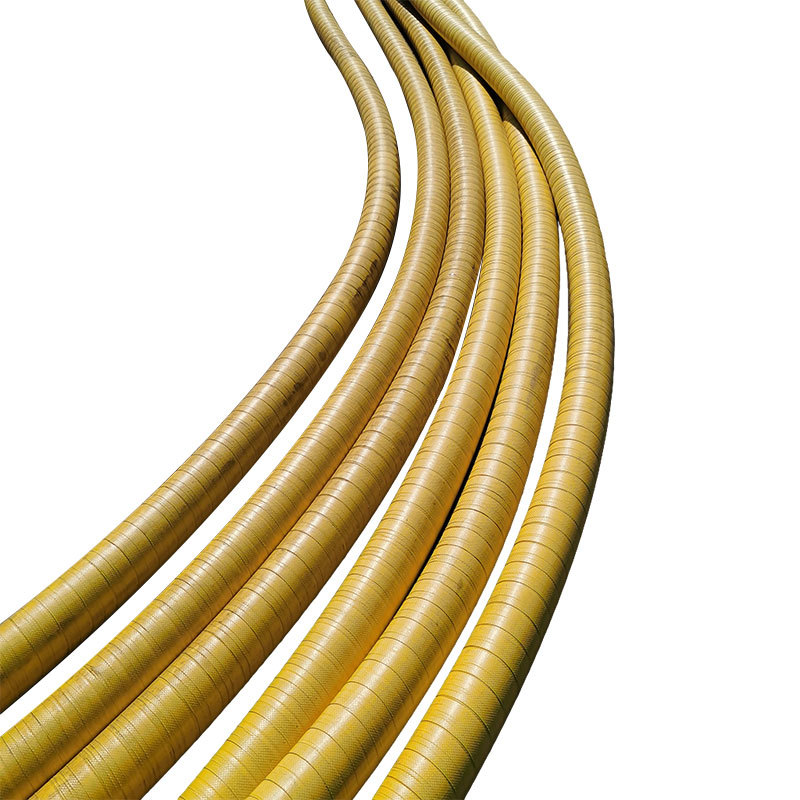

Customized PTFE products

Category:

E-mail:

PTFE products, commonly referred to as those made from Polytetrafluoroethylene (PTFE), are high-performance plastics with many unique physical and chemical properties. Here is a detailed introduction to PTFE products:

Basic Overview

Polytetrafluoroethylene, trademarked as Teflon, is a synthetic polymer produced by the radical polymerization of tetrafluoroethylene monomers. PTFE is renowned for its excellent heat resistance, chemical inertness, and low friction coefficient.

Main Features

1. High Temperature Resistance: PTFE can be used over a long term within the temperature range of -200°C to +260°C and can withstand even higher temperatures for short durations.

2. Chemical Inertness: PTFE exhibits extremely high resistance to most chemicals, including strong acids, strong alkalis, and organic solvents.

3. Low Friction Coefficient: The surface of PTFE is very smooth and adheres to almost no substances, making it an ideal non-stick material.

4. Excellent Electrical Insulation: PTFE is an excellent electrical insulator, suitable for high-frequency and high-voltage applications.

5. Good Biocompatibility: PTFE is harmless to human tissues and is often used in the medical field.

Application Areas

PTFE products are widely used in various fields, including but not limited to:

- Industrial Applications: Used to manufacture corrosion-resistant pipes, valves, pumps, and storage tanks.

- Electrical Equipment: Used to make insulation for high-frequency cables, capacitors, and other electrical components.

- Medical Devices: Used to produce artificial blood vessels, heart valves, and other implantable medical devices.

- Kitchenware: Used to make non-stick pans, baking molds, and other cooking tools.

- Aerospace: Used to manufacture critical components on airplanes and spacecraft, such as seals and insulation materials.

Processing Technology

PTFE can be processed through various methods, including compression molding, extrusion, injection molding, and mechanical machining. Due to its high melting point and low friction coefficient, special techniques and equipment are required during processing.

Environment and Recycling

Although PTFE itself is stable, it decomposes into harmful gases at high temperatures. Therefore, discarded PTFE products need to be properly handled to avoid environmental pollution. Currently, recycling and reusing PTFE remains a challenge.

In conclusion, PTFE products, due to their unique properties, are widely applied in numerous areas and are indispensable materials in modern industry and daily life. With advancements in materials science, the performance and application range of PTFE are expected to expand further.

Related products

Next