Expansion joint

Keyword:

Expansion joint

Category:

E-mail:

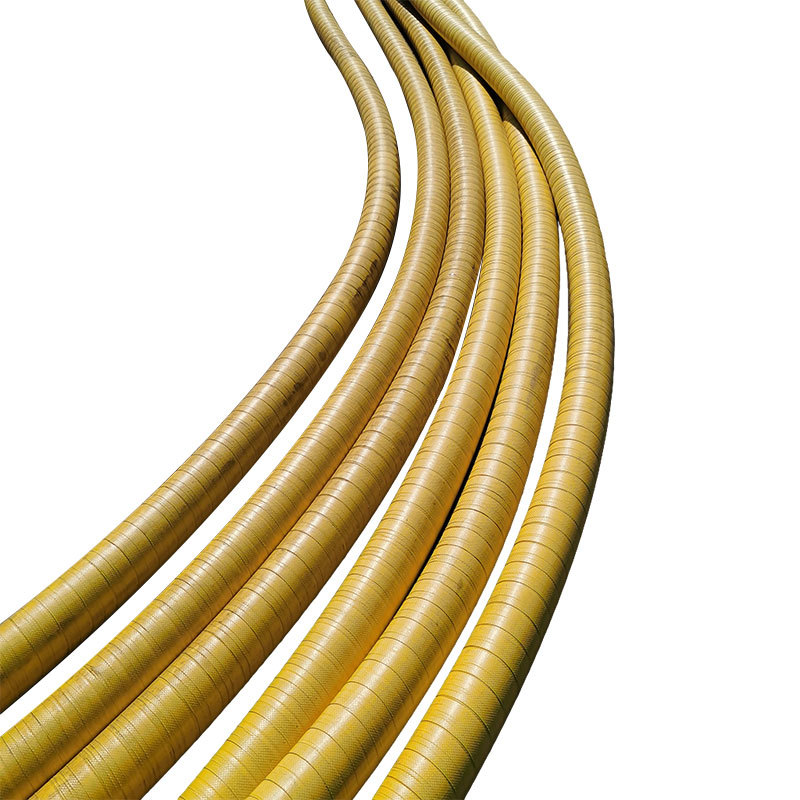

Expansion joints are also commonly known as compensators or expansion joints. It is composed of corrugated pipes (a type of elastic element) and accessories such as end pipes, brackets, flanges, and conduits that make up its working body. Expansion joints are flexible structures installed on container shells or pipelines to compensate for additional stresses caused by temperature differences and mechanical vibrations. By utilizing the effective expansion and contraction deformation of its working body corrugated tube, it can absorb the dimensional changes caused by thermal expansion and contraction of pipelines, conduits, containers, etc., or compensate for the axial, lateral, and angular displacement of pipelines, conduits, containers, etc. It can also be used for noise reduction, vibration reduction, and heating. In order to prevent deformation or damage of the heating pipeline due to thermal elongation or temperature stress when heating up, compensators need to be installed on the pipeline to compensate for the thermal elongation of the pipeline, thereby reducing the stress on the pipe wall and the force acting on the valve or support structure.

Due to its advantages such as reliable operation, good performance, and compact structure, expansion joints have been widely used in chemical, metallurgical, nuclear and other sectors as elastic compensation components that can expand and contract freely. There are various forms of expansion joints used on containers, among which U-shaped expansion joints are the most widely used in terms of corrugated shapes, followed by Ω - shaped and C-shaped ones. In terms of structural compensation, expansion joints used on pipelines can be divided into universal, pressure balanced, hinged, and universal joint types.

Related products

Prev

Next