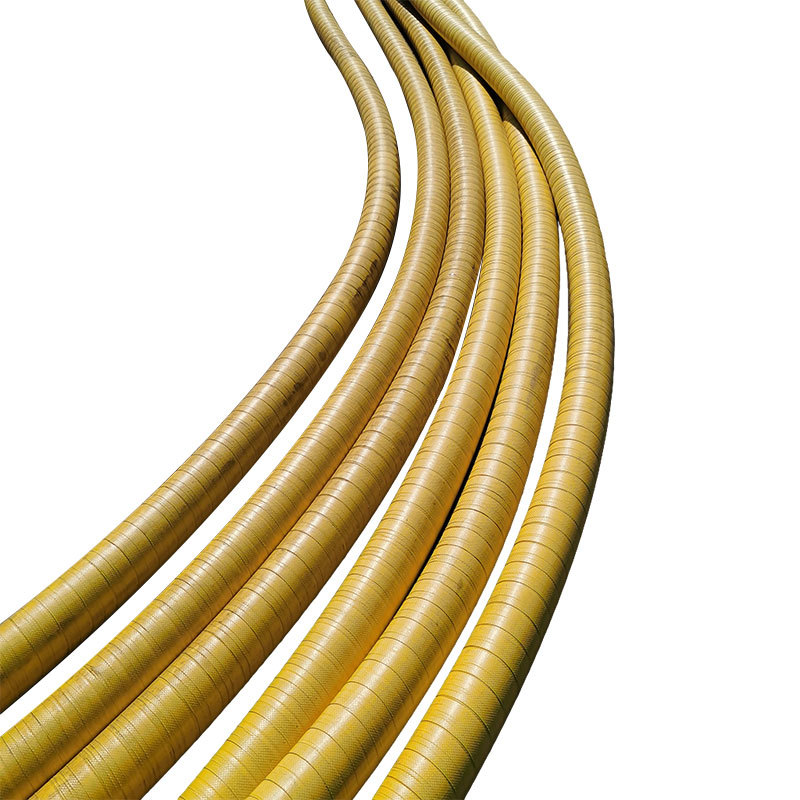

Lined with PTFE metal hose

Keyword:

Lined with PTFE metal hose

Category:

E-mail:

PTFE lined metal hose is a high-performance pipeline accessory, with the following main parameters:

1. Size parameters:

1. nominal diameter: usually ranging from DN8 to DN1200mm, also known as DN15 to DN250, which can be customized according to the needs of the pipeline system.

2. Tube thickness: A flexible hose made of wrapped PTFE tube, generally with a tube thickness of about 1-3mm.

2、 Pressure parameter

1. nominal pressure: usually between 15MPa and 20MPa, also known as compressive energy

PTFE lined metal hose is a high-performance pipeline accessory, and its main parameters are as follows:

1、 Size parameters

1. Nominal diameter: The range is usually between DN8 and DN1200mm, and there are also claims of DN15 to DN250, which can be customized according to the needs of the pipeline system.

2. Tube thickness: A flexible hose made of wrapped PTFE tube, generally with a tube thickness of about 1-3mm.

2、 Pressure parameters

1. Nominal pressure: usually between 15MPa and 20MPa, it is also said that the pressure bearing capacity can reach about 30 kg to 50 kg, depending on the requirements of the pipeline system and the pressure, temperature, and fluid properties in actual applications.

2. Vacuum resistance: Under some standards, the vacuum resistance can reach -0.098MPa.

3、 Temperature parameters

1. Temperature range for use: usually -100 ℃ to+260 ℃, or it is said that the temperature resistance range is between -60 ℃ to+260 ℃, depending on the performance of the PTFE lining material and the design of the hose.

4、 Material parameters

1. Inner lining material: polytetrafluoroethylene (PTFE) pipe, which has good corrosion resistance and low friction coefficient.

2. Reinforcement layer material: Reinforcement materials such as steel wire mesh or stainless steel wire are usually used to improve the pressure bearing capacity and flexibility of the hose.

3. Flange material: 304 stainless steel flange or other materials that meet the requirements, used for connecting and fixing hoses.

5、 Other parameters

1. Connection methods: flange connection, screw symmetrical tightening, buckle connection, etc., can be selected according to actual installation needs.

2. Length: Customizable according to user needs to accommodate different installation spaces and pipeline layouts.

3. Sealing performance: Adopting a sealing structure design, it ensures that the fluid will not leak during transmission and guarantees a clean working environment.

Related products

Next