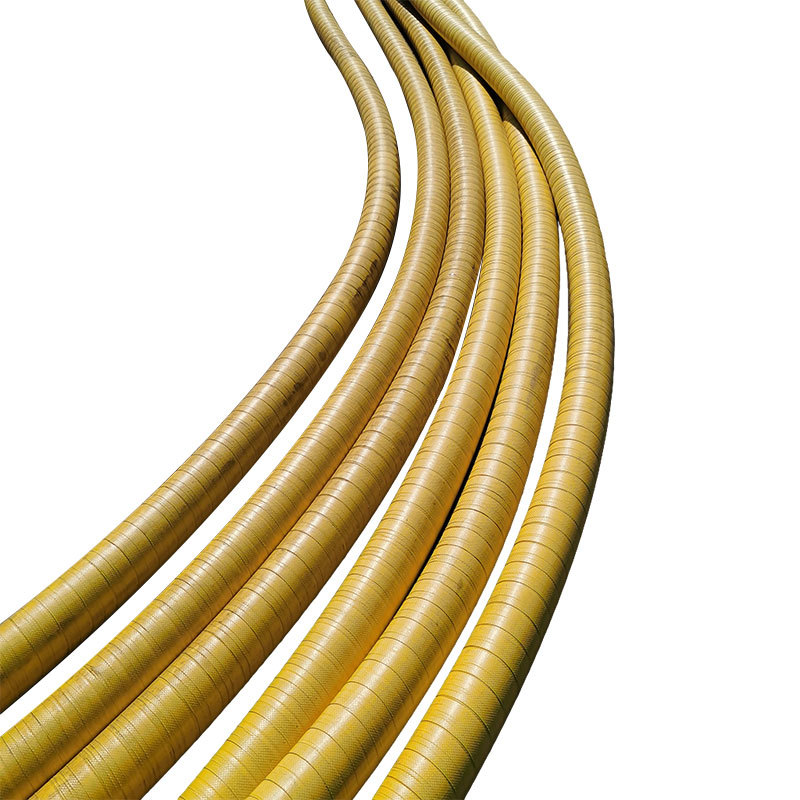

Chuck type metal hose

Keyword:

Chuck type metal hose

Category:

E-mail:

As an important component of metal hoses and other pipeline connectors, the parameters of the chuck are crucial for ensuring the stability of the connection. Here are some common chuck parameters:

1. Basic dimensional parameters 1** Nominal diameter (DN) : Refers to the nominal diameter of the chuck connected pipeline. Common nominal diameters include DN10, DN15, DN20, DN25, DN32, DN40, DN50, DN65, DN80, DN100, etc. Actual dimensions may vary slightly due to differences in standards and manufacturing.

2. Chuck diameter

As an important component of metal hoses and other pipeline connectors, the parameters of the chuck are crucial for ensuring the stability of the connection. Here are some common chuck parameters:

1、 Basic dimensional parameters

1. Nominal Diameter (DN) : Refers to the nominal diameter of the chuck connected pipeline. Common nominal diameters include DN10, DN15, DN20, DN25, DN32, DN40, DN50, DN65, DN80, DN100, etc. Actual dimensions may vary slightly due to differences in standards and manufacturing.

2. Chuck diameter : The outer diameter of the chuck, usually related to the nominal diameter

3. Thickness : The wall thickness of the chuck affects its strength and pressure bearing capacity.

2、 Connection and sealing parameters

1. Sealing surface form : The sealing surface form at the connection between the chuck and the pipeline or equipment, such as flat sealing, convex sealing, mortise and tenon sealing, etc. The selection of sealing surface should be comprehensively considered based on factors such as medium properties, working pressure, and temperature.

2. Sealing Material : A sealing material used for chuck connections, such as rubber, polytetrafluoroethylene (PTFE), graphite, etc. The selection of sealing materials should meet the requirements of corrosion resistance and sealing performance of the medium.

3、 Pressure and temperature parameters

1. Working pressure : The high working pressure that the chuck can withstand, usually expressed in MPa or bar. When selecting a chuck, it should be ensured that its working pressure is higher than or equal to the actual working pressure of the pipeline system.

2. Operating temperature : The high and low operating temperature range that the chuck can withstand. The working temperature range of chucks made of different materials may vary. When selecting a chuck, factors such as the actual operating temperature of the pipeline system and the thermal expansion coefficient of the medium should be considered.

4、 Other parameters

1. Material : The manufacturing material of the chuck, commonly including stainless steel, carbon steel, alloy steel, etc. The selection of materials should be comprehensively considered based on factors such as the corrosiveness of the medium, working pressure, and temperature.

2. Surface treatment : The treatment methods for the surface of the chuck, such as galvanizing, spraying, polishing, etc. Surface treatment can improve the corrosion resistance and aesthetics of the chuck.

Related products

Prev